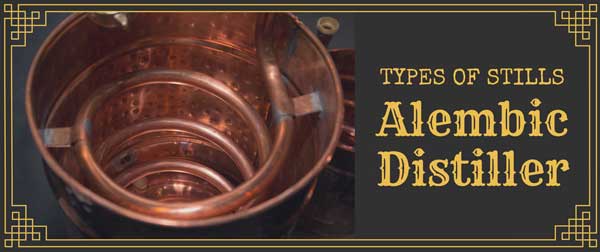

Types of Stills Series: Alembic Distiller

When most people think of a moonshine still, a copper Alembic distiller usually comes to mind. These can be small or large, and are often handmade from copper sheet but not always. Some people have built alembic stills with a stainless steel stock pot or pressure cooker and used copper tubing for the coil because copper can be expensive.

Alembic Distiller

A big benefit that the alembic still has over the stock pot still is that the distillate comes out of the end of the condenser, which allows you to discard the methanol concentrated in the foreshots before collecting what you want to keep. This is also nice because it allows you to keep track of what you collect and see how much distillate you’ve produced.

Here’s how an Alembic distiller works: When the fermented wash is heated to boiling, the vapor rises and passes through a condenser made from cooper tubing, which coils through a separate vessel that is filled with cooling water. The vapor cools and condenses back into liquid, which drips out of the copper tubing and into your collection container.

Some large-scale Alembic distillers are also referred by some folk as “hillbilly” type stills. These types of distillers are kind of a backwoods version of the alembic design created more for yielding a large amount of moonshine than for producing a premium-quality distillate. Hillbilly-type stills typically have kettles that range in size from 50 to several hundred gallons that are heated over an open wood fire. Instead of using a separate vessel filled with cooling water to condense the distillate, the hillbilly type of still incorporates an extra-long coil of copper (called a worm) to cool and condense the vapor using the surrounding outside air.

Comments