Reflux Still Designs Explained: Part 2

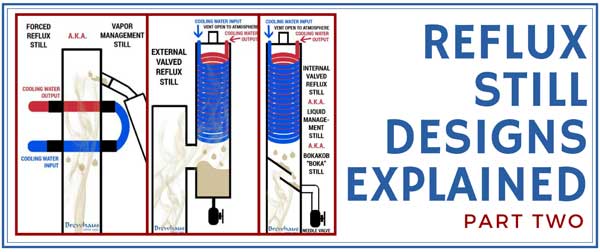

Last week, we printed an excerpt from Rick’s book where he explains the differences in various reflux still designs, including vapor management and water management units. This week, I’m going to respond to some questions that we commonly are asked about our Brewhaus stills using the information from the book.

Why don’t you make stills with a cooling water jacket?

In a nutshell, the jackets are only effective with on a column with a very small diameter (well under 2”). Yes, they look nice, but in practice, this design only allows the vapor at or very near the walls of the column to cool. Vapor towards the center of the column may rise up to the condenser, which leads to a lower purity distillate. Also, the walls of the column are often made with a heavier gauge stainless than what is used for internal cooling lines, which reduces the heat transfer rate. You can also find this info in the excerpt we printed from Rick’s book last week.

Your 3” columns can run nearly twice as fast as your 2” columns. Doesn’t that mean that the distillate won’t be as pure?

I get this question a lot, and I think it’s because this can be true of other reflux still designs. However, our 3” columns are designed to give you the same high-purity distillate as our 2” columns, just in less time. A cooling water jacket design offers faster runs because of a decreased reflux ratio, which leads to lower-purity distillate.

Rick did the math to develop our Pro Series II Reflux Columns using the proper diameter, height, and volume ratios in order to keep the same reflux ratio with our 2” and 3” models. Rick put the condenser above the cooling lines, and he also crossed and increased the number of cooling lines. This lets more vapor come into contact with the cooling lines, allowing more impurities to drop back down the column, and ensuring that only the purest distillate is collected in the condenser.

Liquid Management Stills are so much better than Vapor Management Stills! Why don’t you make those?

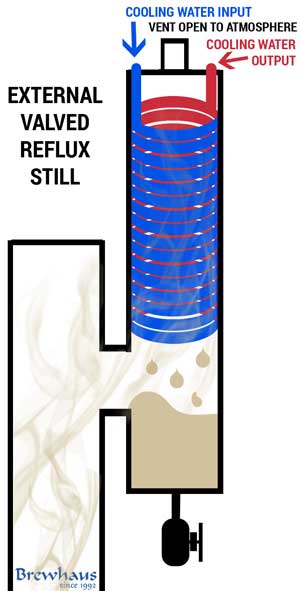

A Bokakob or “Liquid Management” still is the style preferred by those who build their own moonshine stills. It works great because it gives you complete control over your reflux ratio. But all vapor that reaches the top of the column is condensed when it reaches the cooling coil, and then that liquid collects in the reservoir (see diagram). This reservoir allows pure distillate to mix with slightly less-pure distillate on its way to collection.

Every vapor management still design is not created equal, so ask someone who has actually run one of our Pro Series II distillation columns about the purity of their distillate if you’re curious how ours stack up. Rick designed Brewhaus reflux columns to deliver maximum purity, and that’s why we sell this design instead of others.

My friend said to never BUY a still and to just build my own. Is his home-made still better than what you sell?

I can’t answer that because I don’t know the quality of the materials your friend used. I don’t know what design your friend built from. I don’t know what your friend’s welding experience is like. But I do know that Rick is an experienced distiller who had tried a lot of different types of columns and wanted to up his reflux game. He’s a DIY-er with a mathematically-inclined brain (his dad is an engineer), and developed these columns because of what HE wanted out of a still—not so he could mass-produce them and make money. He started Brewhaus in 1992, and for a while he was the only welder here who built stills.

What I do know is that our lead welder, Roman, is certified in sanitary welds and has over 15 years of welding experience in very precise welding for a demanding major company. He and Rick hand-build these columns from stainless steel tubing with equipment made specifically for use with stainless steel. Our kettles are made for us in a manufacturing facility (per Rick’s design and mold) from cookware-grade stainless steel parts that are intended to withstand high temperatures.

If you want to build your own still for the experience, you definitely should. You will learn a lot about the process, and you could make an awesome still. But if you’ve never welded before and you’re not sure that you want to start now, then why are you really building your own? There’s no shame in buying a professional still, and your friend doesn’t have to knock the people who build stills for a living. We love the hobby, too--why do you think we work here?

Any questions?

I’m one of the people that answers the phones when you call Brewhaus, and these were a few of the questions that I get semi-regularly from people who are looking to buy a still. Let me know if I left anything out by messaging me through Facebook! Other people might have the same question, and I’d be happy to write about it.

Comments